Qualification

AMR’s Testing Laboratory allows automatic tests. (digital bench tests).

Tests are driven according to the current norms or to customers specified needs, as well enamel behavior on copper and different bonding tests or dielectrique tests eat…

Why characterize a self bonding wire ?

Standard or not standard tests managed by wires manufacturers have shown their limitations as final customers can obviously notice.

Analysis and test processes must be defined in order to satisfy the different specific customers needs.

Test procedures can be managed with a confidentiality contact with final customers wires manufacturers asking for.

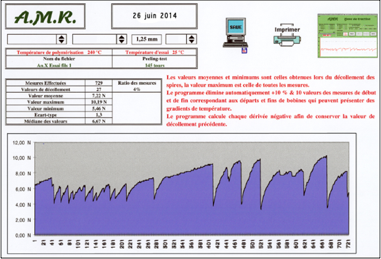

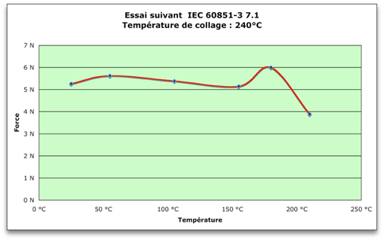

The protocol consists of putting five samples at each points of temperature (25°C,55 °C, 105 °C, 155 °C, 180°C, 210°C) and measure each separation point in order to draw a mini values, max and average.

Residual bonding curve

The previously collected values for characterizing a self bonding wire mechanical temperature resistance.

Mechanical test

AMR has a set of enabling means of achieving the mechanical tests in the field of enameled wire. (Rupture test, Peel test, Springiness measures, Slide test.)

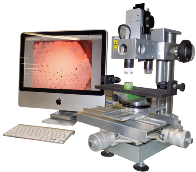

Micro-photography

Optical measurement tools allow visualization of the qualification results.

Analysis wire Ø 0.01 mm