Equipment

CRIMP DIES

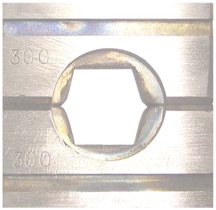

The design of the crimping dies should consider :

- Composition of your cable

- Copper or aluminium cross section

- Your cable geometry (Round, Rectangular or Square)

- From connector use

Step 1 Set up a connector type

We can help you along this step :

- By directing you to the most appropriate connector, according to the different standards.

- By offering a design specific to your needs pods (see page 18)

Step 2 Design and material selection

AMR set a specific geometry of the crimping tools thanks to a computer program taking part in the elements mentioned above, to ensure the optimum mechanical and electrical resistance values.

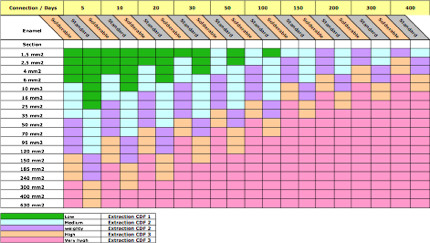

These dies can be cut into different materials in according to the crimping quantity and the type of connector.

Step 3 Identification and markings

Each dies can be identified according to your criteria.

Example : Project Number, Section crimp, Code specific to the company.

The crimped connector will be marked by the dies references.

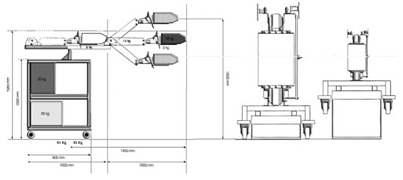

INTEGRATION

AMR achieves the integration according to your specification

- Integration of production line

- Congestion of unit

- Perimeter crimping

- Arm length for deployment

- Mobile or fixed unit

- Smoke extraction system

SMOKE EXTRACTOR