Process

This process, perfected by AMR, ensures the connections of magnet wires :

- Copper or Aluminium,

- Same or different diameters

- Round, flat or CTC

- Single or multi wires

- enamelled, tinned or bare

and that :

-in a same socket

a same terminal

-a same barrel

-a same lug

-standard to all the manufacturers

by :

-heat confining

-soft or hard solder with filler metal

The use of welded wire is no longer inevitable.

The joint action of the couple pressure X heat applied through a socket, barrel, lug or terminal, induces the creeping of the enamel, which ensures the connection of the enamelled magnet wires.

The process is suitable for any composition and any type of enamel.

Thanks to COSDEM, complex compositions (like litz wires cables) can be now used with high performance insulation.

The prospects of technological and economic developments of your coils have currently no limits.

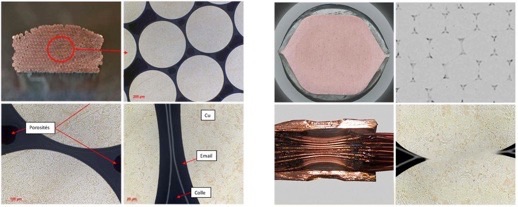

Cross section before crimping

Cross section after crimping